Products

Diethyl monoisopropanolamine

Introduction

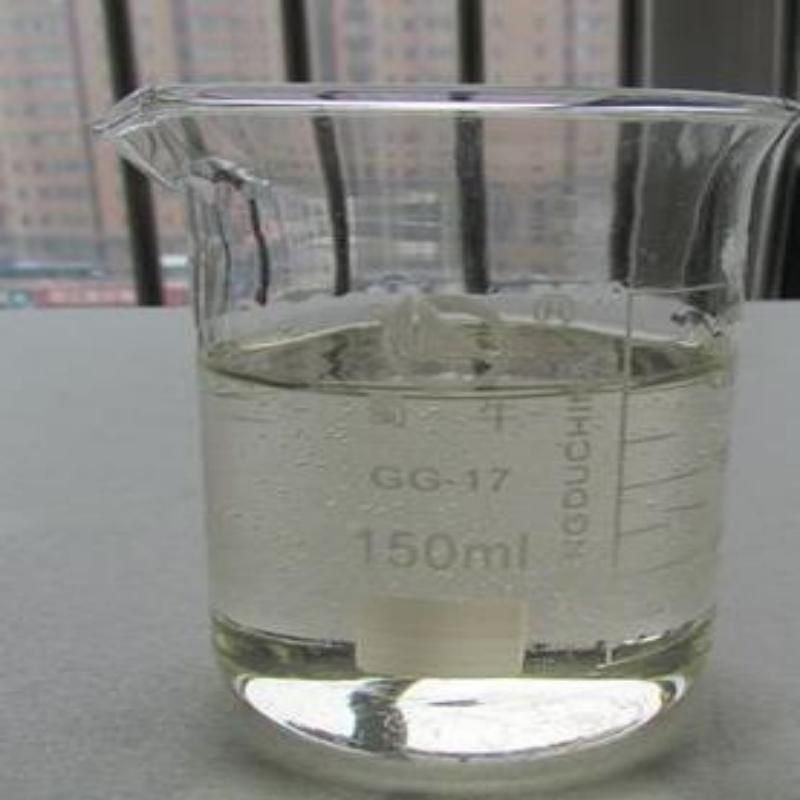

Diethyl alcohol monoisopropanolamine is a kind of organic matter, chemical formula C7H17O3N, colorless or light yellow transparent with ammonia flavor stimulated viscous liquid, stable at room temperature and pressure. Diethyl alcohol monoisopropanolamine is a new type of green grinding aid material, which has obvious grinding aid effect, and is widely used in cement grinding aid.

(1) Diethanolamine monoisopropyl olamine is mainly used in surfactants, widely used in chemical raw materials, pigments, medicine, building materials and other fields, in cement additives, skin care products and textile softener more applications.

(2) At present, in the field of cement grinding AIDS, most of the formulations are single or compound products of alcohol, alcohol amine, acetate and other chemical raw materials. Compared with other similar cement additives, diethyl alcohol monoisopropyl alcohol amine (DEIPA) has great advantages in improving grinding efficiency, energy saving and consumption reduction and improving cement strength.

Production Method

1.The synthesis of monoisopropanolamine (DEIPA) has three main routes: first, the reaction synthesis of ammonia with ethylene oxide (EO) and propylene oxide (PO);

Second, it is formed by the reaction of MIPA and EO. Third, it is synthesized from diethanolamine (DEA) and PO.

2.Ammonia and epoxy olefin reaction route

This route is a three-stage series reaction. Ammonia reacts with EO to produce an ethanolamine, diethanolamine and triethanolamine. The reactants are synthesized with PO, and the target products are obtained after purification. Or, ammonia reacts with PO to produce monoisopropanolamine, diisopropanolamine and triisopropanolamine, and the reactant is synthesized with EO, and the target product is obtained after purification.

3.DEA route

This route uses DEA and PO reaction to produce the target substance DEIPA. The advantage of this route is that the reaction rate is fast, the selectivity of the reaction is high, and the supply of raw materials is sufficient and stable. Our DEIPA production, at present, all use this route, but there is a difference in the production plant or pipeline reaction, in the product isomer and quality stability.